Your height safety system should enable your workers or end-users to safely access areas of your building that require maintenance or ongoing works.

What type of height safety system you require depends on a number of important factors, including:

What type of height safety system you require depends on a number of important factors, including:

There are a range of permanent and temporary solutions for safe high access, and Realm Height Safety can assist you in developing an access plan and selecting the right height safety solutions for your building.

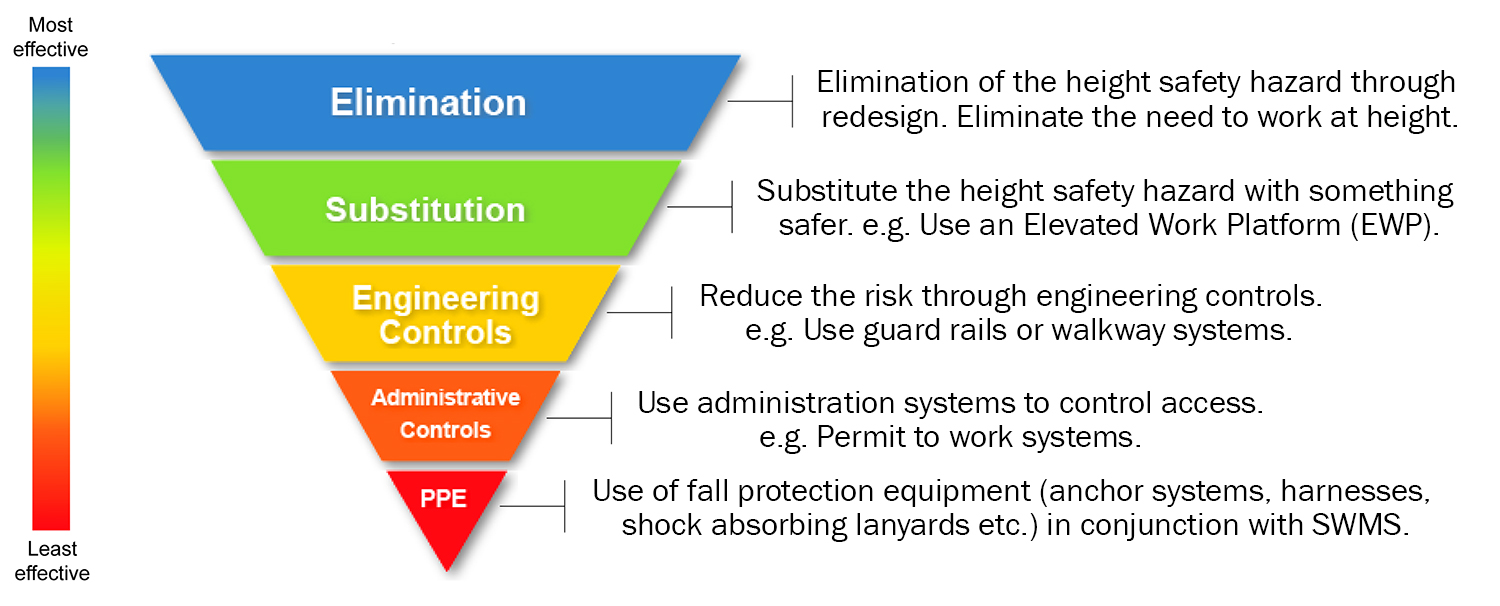

Where possible, the highest level of worker protection in the hierarchy of control is to reduce the risk of a fall. A fall prevention system reduces the risk to the worker or end-user by creating a barrier between them and the fall hazard. Examples include guardrails, skylight protectors, and appropriate signage. A Fall Prevention System requires the least amount of operator training.

Realm Height Safety can also install roof access solutions including rung ladders, fold-down ladders, roof access hatches, and rooftop walkway, which complement fall prevention systems – protecting both the worker and your asset.

Fall restraint systems are much more common, as they are more cost effective. They place more onus on the end user having appropriate working at heights training and competency. They also require safety equipment including harnesses and lanyards that must also be tested regularly.

A fall restraint system allows an end user to access an area near a fall hazard, but stops them from moving beyond the edge. In contrast, a fall arrest system will arrest a fall from height. A fall arrest system will require a more complex rescue plan should retrieval of a fallen worker be required. These systems typically use Fall Arrest Anchors and Static Lines to enable access.

Rope access is typically used for difficult facade access. Typical users include high rise window cleaners, as well as facade maintenance and inspections. Rope Access systems are only to be used by qualified rope access technicians. Rope Access Anchors differ from fall arrest/restraint anchors in that they are designed to hold a static load.

Many times a building has fall-arrest anchors installed and building managers are confused when rope access workers refuse to use the anchors. Fall arrest anchors are usually what is called a “deforming” anchor. It is designed to take energy from the fall, and maintain integrity whilst a rescue is initiated. Rope Access Workers cannot use these anchors as they may deform, and require immediate replacement.

Buildings with overhanging balconies or other architectural features may also have what are called “re-belay” anchors installed. These allow rope access workers to access these difficult areas. These anchors require annual testing through the use of a load-tester. This “pull-test” should be completed to half the rated strength of the anchor.

In both Fall Arrest and Rope Access scenarios, the system requires a timely rescue plan to be effective. Suspension trauma, or orthostatic incompetence, occurs when a worker is suspended upright for more than five minutes with their legs immobile beneath them. When hanging in a harness after a fall, if self-rescue is not possible or there has been a loss of consciousness, blood pools in the legs, becoming toxic and can cause heart failure.

Whilst anchors may sustain the impact loads created during a fall (dynamic loads), they may not be able to handle the additional static load needed to rescue them. A rescue plan cannot use the anchor involved in the fall arrest unless specified by the manufacturer and system designer. Rescue plan are required before work commences and are an essential part of the Safe Work Method Statement (SWMS) required for working safely at height. They will usually require specific training.

Dialling 000 is NOT seen as an effective rescue plan. Response times by emergency services and the need for specialised skills and equipment mean that an on-site capability is required in most cases.

Having a fall arrest system is not enough. Your height safety system must ensure workers are trained in the use of that system, and have appropriate rescue plans in place when working in fall arrest and rope access work methods. Lock-out systems are required to ensure only those who are qualified and have provided appropriate SWMS have access to high risk areas.

Performing a lifetime cost-analysis and understanding your end-users are critical when considering which height safety system is right for your building context. Taking into consideration all of the operational costs, not just initial capital outlay, of your height safety system over a 10 year period, will help you work out the true cost of a typical system. Many elements of fall arrest and static line systems require replacement or assessment after that period including shock absorbers, cables, fittings, harness and lanyards. Additionally, compliance costs, including 12 monthly inspection and re-certification, as well as operator training and lock-out procedures add significant amounts to your operational expenses.

Many of the higher-level solutions in the hierarchy of control such as Engineering Controls make long-term financial sense, as well as reducing overall risk. Financial officers involved in procurement will note the differentiation between operational expenses, and capital outlays (and depreciation allowances) often steer the decision towards higher order controls.

The most efficient system is usually the safest.

As both end-users of height safety systems, and fully-qualified designers and installers, we can help you make an informed choice about your height safety needs.