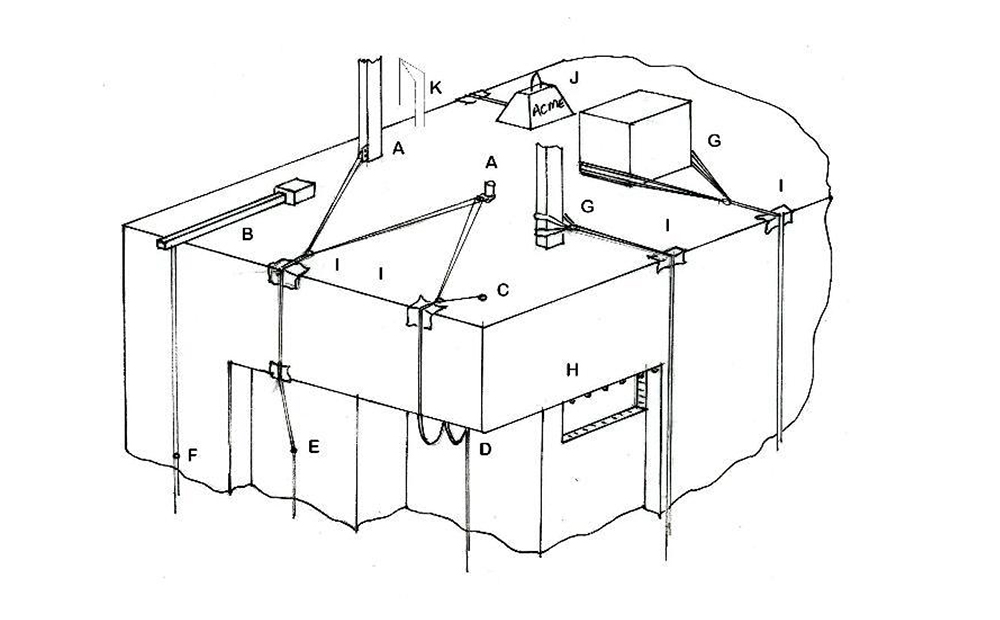

Rope Access allows workers to reach difficult areas on your building facade for maintenance and cleaning purposes. High rise window cleaning, caulking and general maintenance require an anchor system suitable for a minimum of 2 workers on redundant anchors.

Planning for rope access anchors requires a specialist Level 3 Rope Access Technician to ensure the system enables both access to the work areas required, and timely rescue in the event of an emergency.

With a variety of anchor types and options, it is important to have end-user experience when planning a cost-effective and efficient anchor system. We install SAYFA anchors which are designed and manufactured in accordance with requirements of Standards AS/NZS 4488.2:1997, AS/NZS 5532:2013, AS/NZS 1891.4:2009 and relevant statutory OHS Codes of Practice/Guidelines.